ABOUT US

Orotex is one of the pioneers in providing NVH (Noise-Vibration-Harshness) solutions globally to all the automotive industry – supplying rubber & resin based noise insulators, multiple grades of butyl based anti-vibration pads, epoxy based stiffeners and many more

In addition to the automotive industry, we also cater to whitegoods industries such as air conditioners, and also to construction line of business to arrest water leakages on the roofs and joints.

Our parent company, IIDA Industry Co., was founded in 1954, Japan.

Our Mission

- To build a product that causes no unnecessary harm to the environment

- To create a safe & happy working environment

- To create value and make a difference for everyone in the value chain

Mr. Kosuke IIDA

Our Vision

People

Be a safe and happy workplace where people are inspired to be at their best.

Partners

Nurture a winning network of customers and suppliers, together we create mutual, enduring value.

Planet

Be a responsible citizen that makes a difference even though little.

Profit

Maximize long-term return to shareholders while being mindful of our overall responsibilities.

Productivity

Be a highly effective, lean, and fast-moving organization.

Research & Development

Orotex has a strong R&D team of experts constantly working on advanced futuristic technologies with world class instruments creating benchmarks in the NVH industry to meet the diverse needs of customers.

Examples of Analytical Instruments

- Thermo Gravimetry Analyzer

- Differential Scanning Calorimeter

- Dynamic Mechanical Analyzer

- Fourier Transform Infrared Spectroscopy

- X-ray Fluorescence Analysis

- Fatigue Tester

- Universal Tester

Design & Analysis

With our rich and extensive experience in the NVH sector, we offer design solutions and equipment proposals specific to customer requirements that meets cost and performance targets. Finite element method is used for data analysis on product and material properties using various instruments with which you can evaluate the effectiveness of the solution before adopting.

Examples of Design & Analysis Instruments and Software

- 3D CAD (CATIA - NX) Three dimensional computer aided design

- CAE (LS-DYNA / Nastran / Hyper Works) computer aided engineering

Evaluation

From evaluation of sectional part to the evaluation of actual equipment, we are ready and able to present samples that you need. Evaluation can be made at our company or we can dispatch our outstanding testing staff to your company, if needed. Feel free to inquire with us.

Sample Creation / Evaluation

- Laboratory trail manufacture

- Extrusion and injection moulding using the temporary die

- Semi-anechoic room

- Sound absorption coefficient tester

- Sound level meter

- Cyclic Corrosion tester

CERTIFICATIONS

We are Certified

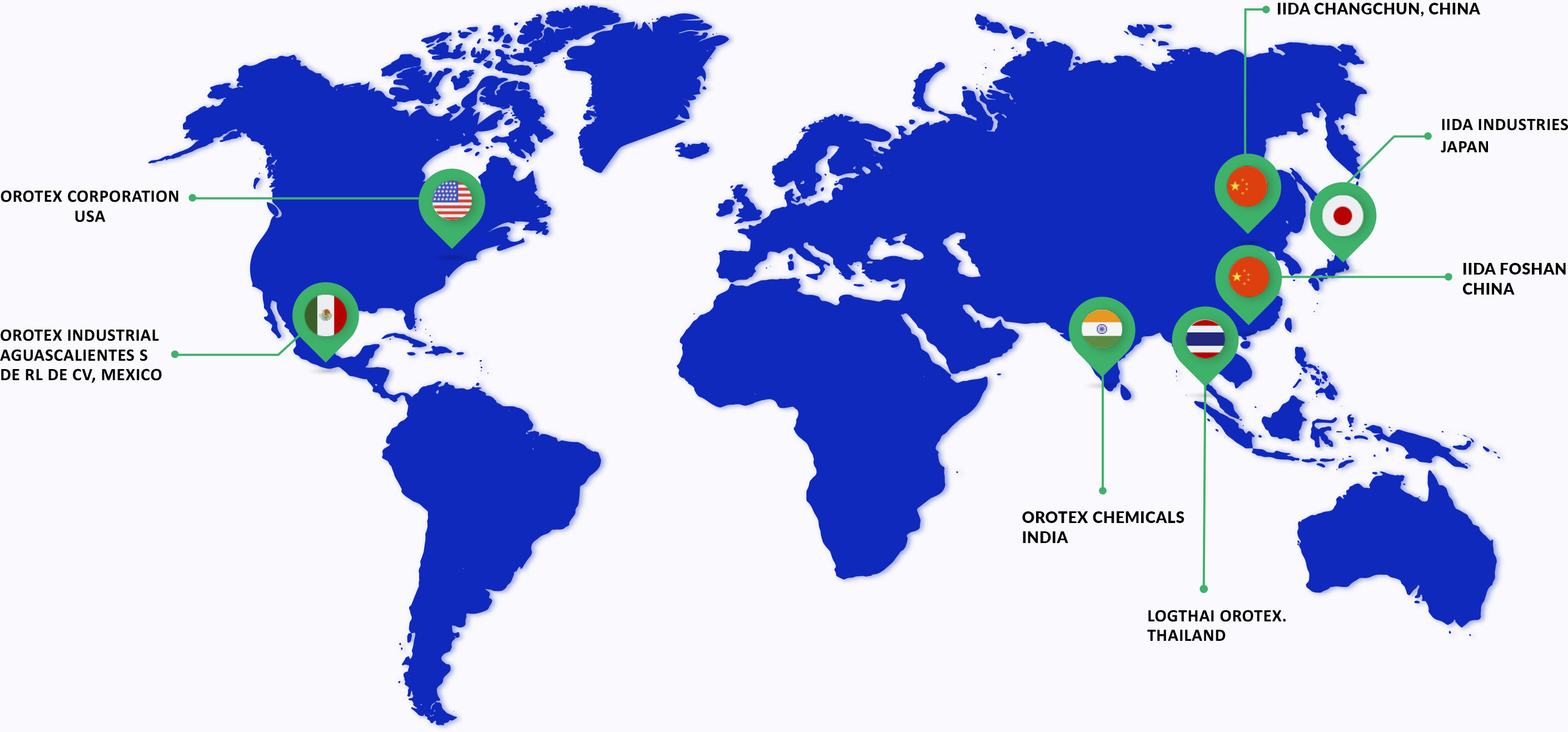

GLOBAL NETWORK

Our Worldwide Presence